HOT ROLLED/MILD STEEL

Mild steel also known as plain-carbon steel, is now the most common form of steel used across all the industrial segments. It is more malleable and ductile & provides material properties that are acceptable for many applications.

Mild steel also known as plain-carbon steel, is now the most common form of steel used across all the industrial segments. It is more malleable and ductile & provides material properties that are acceptable for many applications.

Mild steel has a relatively low tensile strength & density of mild steel is approximately 7.85 g/cm3 (7850 kg/m3 or 0.284 lb/in3)

Read more

COLD ROLLED

Obtained by heat treatment (annealing) and strain-hardening of cold rolled steel in a way to achieve final mechanical properties making the steel suitable for further uses (forming and bending); can be further processed.

Obtained by heat treatment (annealing) and strain-hardening of cold rolled steel in a way to achieve final mechanical properties making the steel suitable for further uses (forming and bending); can be further processed.

They have excellent forming properties, electromagnetic properties, paintability,

weldability, and are suitable for fabrication by forming, pressing and bending.

Applications include domestic applications, automotive applications, lighting fixtures, electrical components (stators, rotors), Control Panel and various kinds of sections roofing applications, profiled sheets, wall elements, etc.

Read more

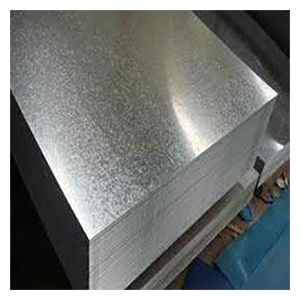

GALVANIZED

Obtained by electro plating finished cold rolled steel with a thin layer of zinc or zinc-nickel to provide corrosion resistance; can be further processed. They have excellent forming properties, paintability, weldability, and are suitable for fabrication by forming, pressing and bending.Applications include domestic applications, building applications (e.g. wall elements, roofing applications), automotive applications (e.g. body in white for vehicles under body auto parts), lighting fixtures, drums and various kinds of sections applications, profiled sheets, etc Read more

Obtained by electro plating finished cold rolled steel with a thin layer of zinc or zinc-nickel to provide corrosion resistance; can be further processed. They have excellent forming properties, paintability, weldability, and are suitable for fabrication by forming, pressing and bending.Applications include domestic applications, building applications (e.g. wall elements, roofing applications), automotive applications (e.g. body in white for vehicles under body auto parts), lighting fixtures, drums and various kinds of sections applications, profiled sheets, etc Read more

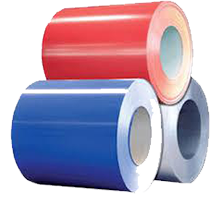

COLOR COATED/PPGI

It is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. Today the term GI typically refers to essentially pure zinc (>99%) continuously hot dip coated steel, The coil coating process may be used for other substrates such as aluminium, or aluminium, stainless steel or alloy coated steel other than "pure" zinc coated steel. However, only "pure" zinc coated steel is typically referred to as PPGI. For example, PPGL may be used for pre-painted 55%Al/Zn alloy-coated steel (pre-painted GALVALUME(r) steel*) Read more

It is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. Today the term GI typically refers to essentially pure zinc (>99%) continuously hot dip coated steel, The coil coating process may be used for other substrates such as aluminium, or aluminium, stainless steel or alloy coated steel other than "pure" zinc coated steel. However, only "pure" zinc coated steel is typically referred to as PPGI. For example, PPGL may be used for pre-painted 55%Al/Zn alloy-coated steel (pre-painted GALVALUME(r) steel*) Read more

TMT

Thermomechanical processing, also known as thermo-mechanical treated bars' (TMT), is a metallurgical process that integrates forging, rolling and/or work hardening with heat-treatment into a single process. The TMT bars have a hard outer surface and a softer core. Their manufacturing process includes hot rolled steel wires passed through water. This makes the surface hard and keeps the core warmer and softer. This helps in making the steel corrosion resistance and also increase its weldability. Read more

Thermomechanical processing, also known as thermo-mechanical treated bars' (TMT), is a metallurgical process that integrates forging, rolling and/or work hardening with heat-treatment into a single process. The TMT bars have a hard outer surface and a softer core. Their manufacturing process includes hot rolled steel wires passed through water. This makes the surface hard and keeps the core warmer and softer. This helps in making the steel corrosion resistance and also increase its weldability. Read more

PIPE & TUBES

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members. There are two technologies that can be used to manufacture steel pipes that can be produced by seamless and ERW Read more

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members. There are two technologies that can be used to manufacture steel pipes that can be produced by seamless and ERW Read more